Lignocellulose to fuel alcohol: current trends

Issue: Biofuels

26 November 2013 article

Liquid transport biofuels are now key contributors to the bioenergy portfolios of many countries. This has been driven by increasing global energy demands together with escalating costs, the environmental unsustainability of petroleum and the finite natural world.

BY GRAEME WALKER

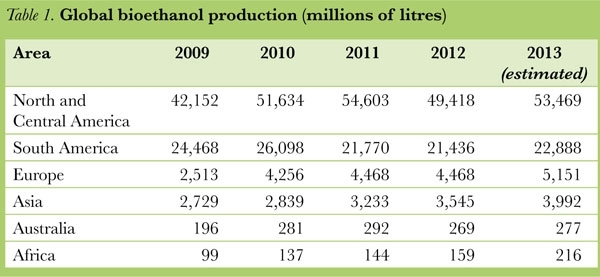

Fuel alcohol, or bioethanol, is by far the most important liquid biofuel in worldwide production today (see Table 1). Current global volumes are over 100 billion litres per annum, with the biggest growth in Europe and Asia.

The world leaders in first-generation fuel alcohol production are the USA (from maize) and Brazil (from sugar cane). France and Germany lead the way in European bioethanol, utilising substrates such as wheat and sugar beet. In the UK, major players in the bioethanol sector are Ensus Energy (Wilton, Teeside), British Sugar (Wissington, East Anglia) and Vivergo Fuels (Saltend, Hull). The latter facility, part-owned by BP, Associated British Sugar and DuPont, has recently opened a £350 million plant to annually process 1.1 million tonnes of wheat to 420 million litres of ethanol, which represents a third of Britain’s current fuel alcohol requirement.

European bioethanol production is increasing year-on-year, mainly in response to national obligations (for example, the Renewable Transport Fuel Obligation, RTFO in the UK) and the 2009 EU Renewable Energy Directive, which aims for biofuels to account for 10% of transportation energy needs by 2020.

Produced by the fermentation of plant biomass sugars, bioethanol is totally renewable since the carbon dioxide (CO2) liberated in its combustion is reassimilated by photosynthesis in the growing plants that are the biofuel feedstocks. In particular, ethanol produced from lignocellulosic biomass represents a sustainable (non-food) renewable energy source for transportation that can reduce dependence on fossil fuels as well as minimise greenhouse gas emissions.

Lignocellulose feedstocks for biofuels

Lignocellulosic biomass is the most abundant source of carbon on this planet and is primarily comprised of cellulose, hemicellulose and lignin. Typical lignocellulosic biomass material, such as woody biomass from poplar trees, would contain (on a dry weight basis): 45–50% cellulose, 17–19% hemicellulose and 18–20% lignin. The latter is a non-fermentable polyphenolic compound, whilst both cellulose [a homopolymer of glucose in β-(1–4)-linkages] and hemicellulose (a branched heteropolysaccharide with pentoses such as xylose and arabinose, and hexose sugars such as glucose, mannose and galactose) can yield fermentable sugars following hydrolysis.

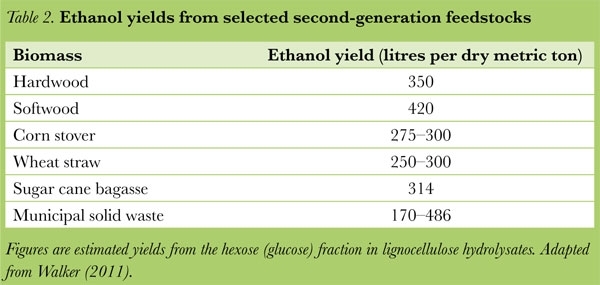

Bagasse is the fibrous residue following extraction of juice from sugar cane stems, and is the most abundant agricultural residue in Brazil, India and China. In North America, Europe and parts of Asia, the most abundant residue is straw from cereals such as maize, wheat, rice and barley. Both bagasse and straw, together with other sources of lignocellulose (listed in Table 2), have great potential for the production of second-generation ethanol. Other lignocellulosic materials that are attracting a lot of attention for bioethanol production include the ‘energy crops’, such as Miscanthus, short-rotation willow and poplar, ryegrass and giant reed.

Current scientific and technological challenges

Lignocellulosic ethanol represents a sustainable alternative to petroleum-based transportation fuels. However, bioprocessing of feedstocks is difficult and expensive with the major impediments for commercialisation being feedstock pre-treatment, saccharification and efficient microbial fermentation of lignocellulose-derived sugars toethanol. When using harsh thermochemical means to deconstruct the starting material, the use of acids and high temperatures can liberate toxic chemicals (such as acids, phenols, furans), which are inhibitory to subsequent cellulolytic enzymes and the microbes conducting the fermentation. One of the major microbiological challenges for bioethanol production from lignocellulose lies in the difficulty to fermentxylose, the second most abundant sugar in the biomass after glucose, to ethanol. The yeast Saccharomyces cerevisiae, which is widely used in brewing, distilling and wine fermentations, cannot directly convert this sugar to ethanol and so the use of alternative micro-organisms, or genetic engineering of S. cerevisiae, are the approaches for high yields of ethanol from lignocellulosic sugars. Some natural xylose-fermenting yeasts, such as Scheffersomyces stipitis, have been considered but they do not produce high levels of ethanol from xylose under anaerobic conditions. This is due to a redox imbalance that results in xylitol accumulation. The genetic modification of S. cerevisiae with bacterial or yeast xylose metabolism genes is an area of active research and development. For example, the use of bacterial or fungal xylose isomerase appears promising as it avoids any redox imbalance, but resultant transformed strains need to survive the rigours of industrial fermentation conditions and this is proving difficult.

Global players in cellulosic alcohol

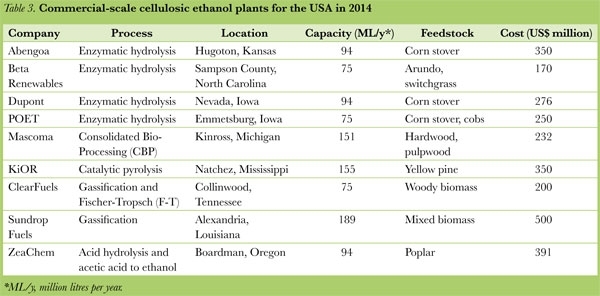

For second-generation fuel alcohol production, the USA leads the way (see Table 3), but the world’s first commercial-scale cellulosic ethanol production plant was established in Italy in 2012: Beta Renewables in Crescentino. This plant produces 75 million litres of ethanol per year from wheat and corn straw (in summer), rice straw (winter) and eucalyptus (in-between). In the UK, TMO Renewables, based in Guildford, aim to exploit the properties of thermophilic bacteria such as Geobacillus spp. (rather than yeasts), which can effectively bioconvert lignocellulosic substrates to ethanol at high temperatures. The company have demonstration plants in England and other locations.

Future developments

Although there are many demonstration-scale lignocellulose ethanol plants operationalthroughout the world, commercial-scale production is still in its infancy. Nevertheless, there are some large plants in Europe and in the USA and these are doubtless the progenitors of more widespread facilities yet to be constructed. In the UK, there is tremendous potential to utilise residual biomass from agricultural, industrial and forestry practices. Additionally, municipal solid waste, urban green wastes (councils and domestic) and food wastes (households, hotels, supermarkets, restaurants) could be considered as available and sustainable feedstocks for fuel alcohol production in the future. We await the political and economic stimuli for industry to commence their biotechnological exploitation.

In conclusion

- Lignocellulosic ethanol has many socio-economic advantages (versus starch/sugar).

- Pre-treatment and hydrolysis is difficult, but not impossible.

- Inhibitory chemicals are problematic.

- GM microbes can now ferment C6 and C5 sugars.

- Full commercialisation is now here!

Graeme Walker

University of Abertay, Dundee DD1 1HG, Scotland, UK

Email: [email protected]

Further reading

Walker, G.M. (2011). Fuel alcohol: current production and future challenges. Journal of the Institute of Brewing 117, 3–22.

Walker, G.M. (2013).Bioethanol: science and technology of fuel alcohol. Copenhagen: Ventus Publishers (www.bookboon.com).

Image: Green sugar cane iStock/Thinkstock. Longitundinal section through a maize (Zea mays) root tip, viewed using a confocal microscope Jim Haseloff/Wellcome Images. Polarised light micrograph of glucose crystals Stefan Eberhard/Wellcome Images..