Biohydrogen - a clean fuel but a dirty business

26 November 2013

Harnessing hydrogen gas as a replacement fuel for transport could help reduce pollution, but are there ways to generate it to make it a viable option? Could microbes or enzymes interact to produce hydrogen gas on a mass scale?

BY FRANK SARGENT & CIARÁN L. KELLY

Hydrogen gas (H2) is an essential, industrial commodity. It plays indispensable roles in many important industrial processes, including the hydrogenation of fats and oils as well as methanol and ammonia production. H2 is also used in refineries to remove pollutants and in the conversion of crude oil to other chemicals, including jet fuel. Moreover, H2 is heralded by many as an exciting alternative to petroleum-based transportation fuels, since its combustion yields nothing but pure water. Indeed, burning H2releases the highest energy-per-mass of any known fuel, and as a result a H2/O2 (hydrogen/oxygen) mixture is the propellant of choice for sending spacecraft into orbit. It is easy to forget that H2 gas used to be a common feature of domestic fuel in the very recent past; it was the dominant component of coal gas in the 19th and 20th centuries. While modern energy companies remain predisposed with a perverse attempt at re-living the industrial revolution by burning fuel to produce steam that drives turbines generating electricity, H2 has the advantage of being slightly more sophisticated. H2 can be used directly in fuel cells to very efficiently generate electricity at ambient temperature, again with water vapour as the only emission. So-called 'Hydrogen Highways' were once planned in most developed countries with the aim of encouraging the use of vehicles powered by H2 fuel cells.

The bad news is that currently 99% of H2, in use by industry, is produced by steam-reformation of natural gas, which requires a large energy input and produces huge amounts of greenhouse gas. For example, worldwide ammonia production in 2009 required 23 million metric tonnes of H2, resulting in 198 million metric tonnes of carbon dioxide (CO2) emissions. As important as H2 is as a chemical feedstock and as an alternative and versatile fuel, the current methods of H2production are unsustainable.

Microbes and biohydrogen production

Naturally produced hydrogen gas has a critical place in the metabolism of many microbes, including photosynthetic microalgae and cyanobacteria, strictly anaerobic bacteria such as the clostridia, nitrogen-fixing soil bacteria such as Rhizobium and Azotobacter, as well as enteric bacteria such as Escherichia coli. There is another chemical reaction that is equally as important; H2 oxidation (sometimes called H2 ‘uptake’), where H2 is predominantly used as an energy source. This activity is important in extremophiles and many other bacteria. In fact, in opportunistic pathogens that infect humans, such as Helicobacter and Mycobacterium, H2 uptake is often central to the infection process.

The ability of living microbes to produce ‘biohydrogen’ offers the prospect of fully renewable hydrogen, freed from any dependence on fossil fuel, and the scope for tapping into this resource is potentially enormous. Microalgae are photosynthetic autotrophs that can produce H2 under some conditions. Thus, harnessing algal systems could address many problems at once. For example, algae could grow in sunlight fixing CO2 (a greenhouse gas) from the atmosphere and producing H2 gas in addition to high-value products such as lipids and other chemicals. In reality, the amounts of H2 produced are low and sporadic, usually coinciding with darkness, anoxia, or other stresses such as sulfur or nitrogen limitation.

With other biofuel technologies moving more into plant biomass and agricultural or food waste processing, it may be that ‘dark fermentation’ is the future of biohydrogen fuel production. In theory, hydrolysis of one molecule of glucose could produce 12 molecules of H2, but in practice fermentative bacteria such as Clostridium acetylbutylicum or E. coli only produce about two to three H2molecules per glucose metabolised. Some thermophilic organisms, such as Caldicellulosiruptor saccharolyticus, can produce slightly more biohydrogen, depending on the type of sugar fermented, but it remains an inefficient process. Although fermentative biohydrogen production usually produces some CO2, the CO2 production is considered ‘carbon neutral’. This is because the sugars fermented by microbes during dark fermentation are all derived from plants, which themselves have originally generated those sugars from atmospheric CO2. Thus there is no net increase of CO2 in the atmosphere. The biohydrogen produced here is usually also free of contaminating hydrogen sulfide or other gases, and so can be used directly in a fuel cell to generate electricity.

Hydrogenases: enzymes of the past, enzymes of the future

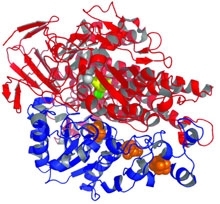

Hydrogenases are the extremely active enzymes responsible for the vast majority of microbial H2production. They are thought to be among the most ancient of enzymes, tracing back over 3.6 billion years to when the Earth’s atmosphere was thick with H2 and completely devoid of oxygen. The two main classes of hydrogenase are known as [FeFe] and [NiFe] according to the metals contained at their catalytic centres. They perform a remarkable chemical reaction by combining protons (H+) with electrons (basically electricity) to generate H2, and they are said to perform this reaction even more efficiently than the best platinum catalysts currently available. It is possible to isolate hydrogenase enzymes, hook them up to a source of electrons (an electrode), and then drive H2 production in the test tube. It is also possible to couple these enzymes with different ones (such as laccases, which are copper-dependent oxidases, or carbon monoxide dehydrogenases) to generate bio-batteries or other H2-producing devices. Attempts have even been made to connect hydrogenases directly to photosynthetic complexes in an effort to generate biohydrogen directly from sunlight. Unfortunately, the problems with hydrogenases are that they are fragile and often inactivated by oxygen, an element that pervades our atmosphere. Recent studies of hydrogenases that can function in air (so-called ‘oxygen-tolerant’ hydrogenases) may hold the key to moving this technology forward.

Natural or synthetic solutions

In order for biohydrogen to become a viable commercial fuel, an increase in yield is required, or the coupling of biohydrogen production directly to production of another, much more valuable, biochemical, will be necessary. While it is possible that bioprospecting on planet Earth might uncover a natural organism that delivers a high yield of H2from cheap substrates, it is likely that synthetic approaches will be needed to speed things along. Microbes can be modified to express non-native enzymes, and metabolic engineering can be used to guide metabolic flux towards hydrogen production. For example, rates and yield of H2 production by E. coli can be significantly boosted using these types of synthetic biology approaches. However, it is the ability to engineer and mimic new systems based on the internal structure of the hydrogenase enzymes themselves that could bring the biohydrogen component of a future renewable energy sector much closer. Chemists can already make compounds that mimic the chemically active site of hydrogenase – and so produce H2 in vitro. The next challenge faced by society and scientists is to harness the isolated enzymes and control their ability to interconvert electricity and H2 gas.

Frank Sargent and Ciaran L. Kelly

College of Life Sciences, University of Dundee, Dow Street, Dundee DD1 5EH, Scotland, UK

Email: [email protected]

Further reading

Jones, C.S. & Mayfield S.P. (2012). Algae biofuels: versatility for the future of bioenergy. Current Opinion in Biotechnology 23, 346–351. doi:10.1016/j.copbio.2011.10.013.

Ogo, S. & others (2013). A functional [NiFe]hydrogenase mimic that catalyzes electron and hydride transfer from H2. Science 339, 682–684. doi:10.1126/science.1231345.

Parkin, A. & Sargent, F. (2012). The hows and whys of aerobic H2metabolism. Current Opinion in Chemical Biology 16, 26–34. doi:10.1016/j.cbpa.2012.01.012.

Xu, L. & Armstrong, F.A. (2013). Optimizing the power of enzyme-based membrane-less hydrogen fuel cells for hydrogen-rich H2 – air mixtures. Energy and Environmental Science 6, 2166–2171. doi:10.1039/c3ee40791h