Using bacteria to develop sustainable infrastructure

The Microbiology Society is undertaking a project entitled A Sustainable Future as part of our 75th Anniversary, which aims to highlight the Sustainable Development Goals (SDGs) to our members and empower them to use their research to evidence and impact the goals. Earlier this year, we put a call out to our members to submit case studies in the following three areas: antimicrobial resistance, soil health and the circular economy.

This case study is written by Dr Susanne Gebhard, who is a Senior Lecturer at the University of Bath, UK. It focuses on the circular economy; an alternative to a traditional linear economy (make, use, dispose), in which we keep resources in use for as long as possible, extract the maximum value from them while in use, then recover and regenerate products and materials at the end of each service life.

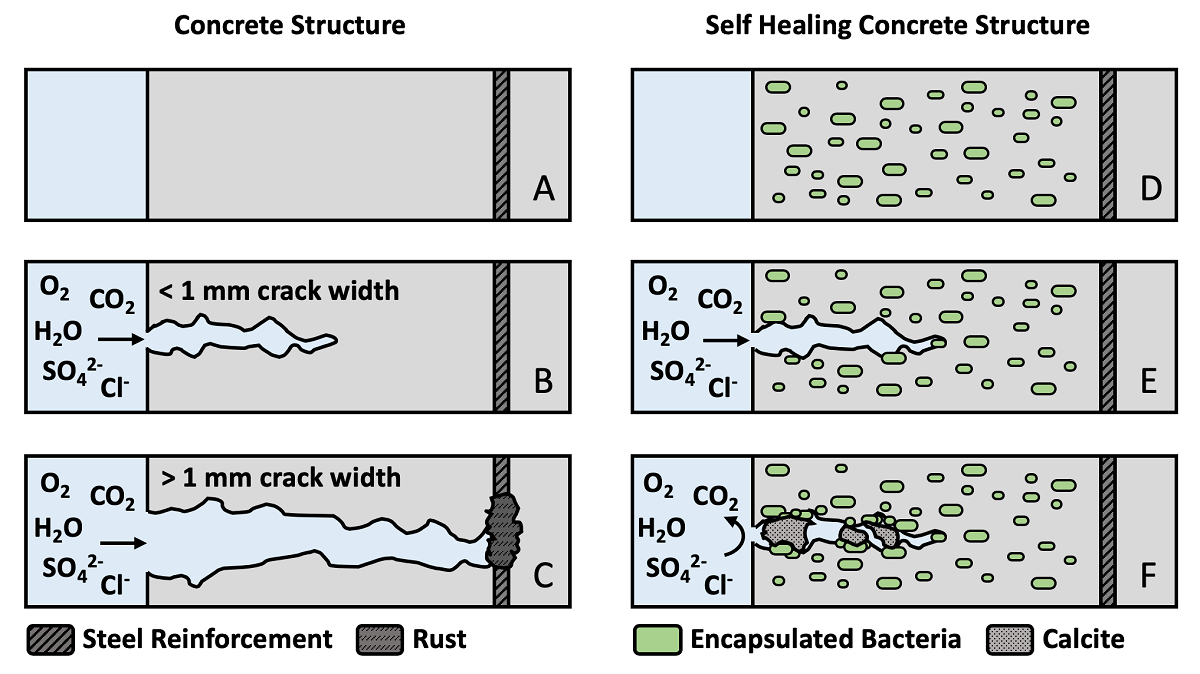

Concrete is the most widely used building material in the world today. It is cheap, can bear the large weights required to build tall structures, and it can be cast into many different shapes. However, it comes at a large environmental cost, with cement production being responsible for about 8% of anthropogenic carbon dioxide emissions. This is made worse by durability issues because concrete is prone to cracking under tension. Initially, such fissures are small, below 1 mm in width, and do not impair the concrete’s performance. However, water ingress through such hairline cracks triggers corrosion of internal steel reinforcements, causing deterioration of the structure and eventually requiring repair or even replacement. Novel technologies that prolong the lifetime of concrete structures could therefore offer valuable contributions in meeting the United Nations (UN) Sustainable Development Goals (SDGS) on industry, innovation and infrastructure, as well as climate action.

At the University of Bath, we are pioneering the use of bacteria in sealing the early-stage hairline cracks to restore water tightness and thus long-term integrity of concrete. Our central aim is to embed the bacteria in the concrete when it is first cast, in a way that allows the bacteria to emerge when a crack appears, and seal it without the need for human intervention. Developing such ‘self-healing’ concrete requires a multi-disciplinary team of microbiologists, concrete technologists and civil engineers. We also work closely together with partners from the Universities of Cardiff and Newcastle, on mathematical modelling of crack formation and bacterial healing to fully understand the processes from the micro to the macro scale.

Our technology hinges on the ability of many bacteria to precipitate minerals in their environment. This process of biomineralization has contributed to forming the geological features of our planet and is now increasingly exploited for biotechnological applications.

In the high-calcium environment of concrete, the mineral that will be formed is calcite, i.e. limestone, and it is easy to envision that limestone formation in a crack will be able to repair concrete. There are, however, challenges in achieving this. For example, the pH level of concrete is extremely high, starting at pH 13 in new structures, and slowly decreasing to around pH 9 as it ages. Moreover, as concrete sets, it can heat up to high temperatures, and the pore volume within hardened concrete is smaller than the size of a bacterial cell. Finally, the bacteria will require some form of nutrients to proliferate upon crack formation.

To ensure the survival of the bacteria, we are focusing on alkaliphilic, spore forming bacteria. These bacteria thrive at pH 9 and above and their spores can survive the heat production during concrete setting. We have also developed a methodology to encase the bacterial spores in lightweight aggregates, where they are protected from any crushing forces. Once the concrete cracks the aggregates are also broken and the bacteria are released. Our current technology can provide the nutrients required for bacterial growth either by direct addition of organic substrates, e.g. yeast extract, to the wet cement paste, or by encapsulating the nutrients in the same way as the bacteria.

Testing our technology at laboratory scale has shown that the embedded bacteria can indeed emerge after crack formation and seal cracks of about 0.5 mm width. Not only are the cracks visually sealed after a few weeks of bacterial healing, the water tightness of our test specimens is nearly restored to the levels of uncracked samples. Embedding this technology in new concrete infrastructure could thus prolong its lifespan, by ensuring that initial hairline cracks are quickly sealed, and detrimental water ingress is prevented.

The self-healing nature of our technology will be particularly relevant in hard-to-reach structures such as bridges, tunnels or underground pipes. We also envision the broader impact of this technology by applying it to surface repair of existing infrastructure, e.g. as a spray-on solution or paint, which would not require encapsulation. We are working closely with a range of industrial partners to identify their needs and develop our technology accordingly.

A number of challenges that remain with this new technology are now being addressed by our research team. One key benefit of concrete as a construction material is its low cost. Any self-healing technology must therefore also be cost-effective. We are investigating alternative encapsulation techniques or sources of nutrients for the bacteria. The latter offers opportunities for further improvement on sustainability, e.g. by exploiting organic waste materials. Designing out waste and keeping materials in use are key concepts of a circular economy that our self-healing concrete application can help to address. We are also expanding the range of conditions under which our bacterial self-healing concrete can perform, for example in low-temperature or low-oxygen environments. Here, we tap into the enormous talent pool that evolution has provided in the form of microbial biodiversity. As every habitat on Earth, no matter how extreme, contains microbes that thrive under those conditions, we are confident that we will be able to expand our self-healing technology to suit a breadth of applications and bring us one step closer to a truly sustainable infrastructure.

Project team (University of Bath):

Susanne Gebhard (PI, Dept. of Biology & Biochemistry)

Kevin Paine (PI, Dept. of Architecture & Civil Engineering)

Bianca Reeksting (PDRA, Dept. of Biology & Biochemistry)

Charlotte Hamley-Bennett (PDRA, Dept. of Biology & Biochemistry)

Ismael Justo-Reinoso (PDRA, Dept. of Architecture & Civil Engineering)

Timothy Hoffmann (PhD student, Dept. of Biology & Biochemistry)

Linzhen Tan (PhD student, Dept. of Architecture & Civil Engineering)

Lorena Skevi (PhD student, Dept. of Architecture & Civil Engineering)

Andrew Heath (Co-I, Dept. of Architecture & Civil Engineering)

Veronica Ferrandiz-Mas (Co-I, Dept. of Architecture & Civil Engineering)

Collaborators:

Tony Jefferson (University of Cardiff)

Dana Ofiteru (Newcastle University)

Funding:

EPSRC programme grant “Resilient Materials for Life (RM4L) (EP/P02081X/1)

EPSRC standard grant “Engineering Microbial-Induced Carbonate Precipitation via Meso-Scale Simulations” (EP/S013857/1)

About the Author

Dr Susanne Gebhard is a Senior Lecturer at the Department of Biology & Biochemistry at the University of Bath, UK. More information about her work is available here.