Bio-upcycling of plastic waste

The Microbiology Society is undertaking a project entitled A Sustainable Future as part of our 75th Anniversary, which aims to highlight the Sustainable Development Goals (SDGs) to our members and empower them to use their research to evidence and impact the goals. Earlier this year, we put a call out to our members to submit case studies in the following three areas: antimicrobial resistance, soil health and the circular economy.

This case study is written by Tanja Narancic, Assistant Professor at the University College Dublin, Ireland. It focuses on the circular economy; an alternative to a traditional linear economy (make, use, dispose), in which we keep resources in use for as long as possible, extract the maximum value from them while in use, then recover and regenerate products and materials at the end of each service life.

Traditional plastics are fossil-based versatile materials, with excellent properties such as strength, flexibility, lightweight, and easy and low-cost production. This makes them ideal materials for application in a large number of industrial and consumer products. While they are beneficial in many ways, such as helping to reduce food waste by providing good barrier properties and therefore decrease food spoilage, and as lightweight packaging materials actually decrease transport related greenhouse gas emissions (i.e. transport in glass bottles versus polyethylene terephthalate (PET) bottles), the ‘take-make-dispose’ culture associated in particular with single-use plastics has resulted in serious plastic waste accumulation. In addition to this, some plastic waste management options such as incineration, lead to the loss of a very valuable resource. The circular economy of plastics aims to retain the value of the material through, reuse, recycling, and other recovery. However, recycling as an option remains largely unexploited, likely due to the high price and low quality of the recyclate.

What could be the role of micro-organisms in the circular economy of plastics?

In addition to providing enzymes for biological depolymerisation and bio-recycling of plastics such as PET1, micro-organisms have evolved to utilise a wide range of carbon and energy substrates, including plastics or plastic-derived molecules. Use of post-consumer plastic as a non-conventional feedstock with the capacity of micro-organisms to produce value-added molecules, such as biodegradable plastics and chemicals, should be a perspective of the circular economy of plastics2. In this perspective, micro-organisms are used as biocatalysts to upcycle rather than recycle post-consumer plastic.

A recent EU Horizon 2020 project titled “From Plastic waste to Plastic value using Pseudomonas putida Synthetic biology (P4SB)” combined four research lines: enzymatic plastic depolymerisation, microbial metabolism of the obtained plastic monomers, production of a biodegradable plastic polyhydroxyalkanoate (PHA) and other valuable molecules, including subsequent purification, to offer a novel approach to valorising plastic waste. These research lines were underpinned by synthetic biology and model-driven development of enzymes, bacteria and processes. One of the many successful project outputs is a multidisciplinary approach to upcycle PET into PHA and a novel, partly bio-based poly(amide urethane) (bio-PU)3. The advantage of this approach is that the enzymatically depolymerised PET can be directly used as a feedstock for a bacterium, circumventing the need to purify the products of enzymatic hydrolysis, which could be a costly process. Metabolic engineering approaches, ranging from simple manipulations to systems metabolic engineering, referring to the manipulation of the whole cell organisation and function, have greatly expanded the repertoire of industrially relevant compounds that can be accessed by biocatalysis. In our efforts to diversify the portfolio of products obtained by PET upcycling, the consortium of researchers collaborated to engineer a bacterium to produce and secrete hydroxyalkanoic acids (HAAs). HAAs are amphiphilic molecules with surfactant properties. They are also interesting platform chemicals for further bio- or chemo-catalytic conversion, which we have demonstrated by using HAAs to make another plastic polymer: bio-PU.

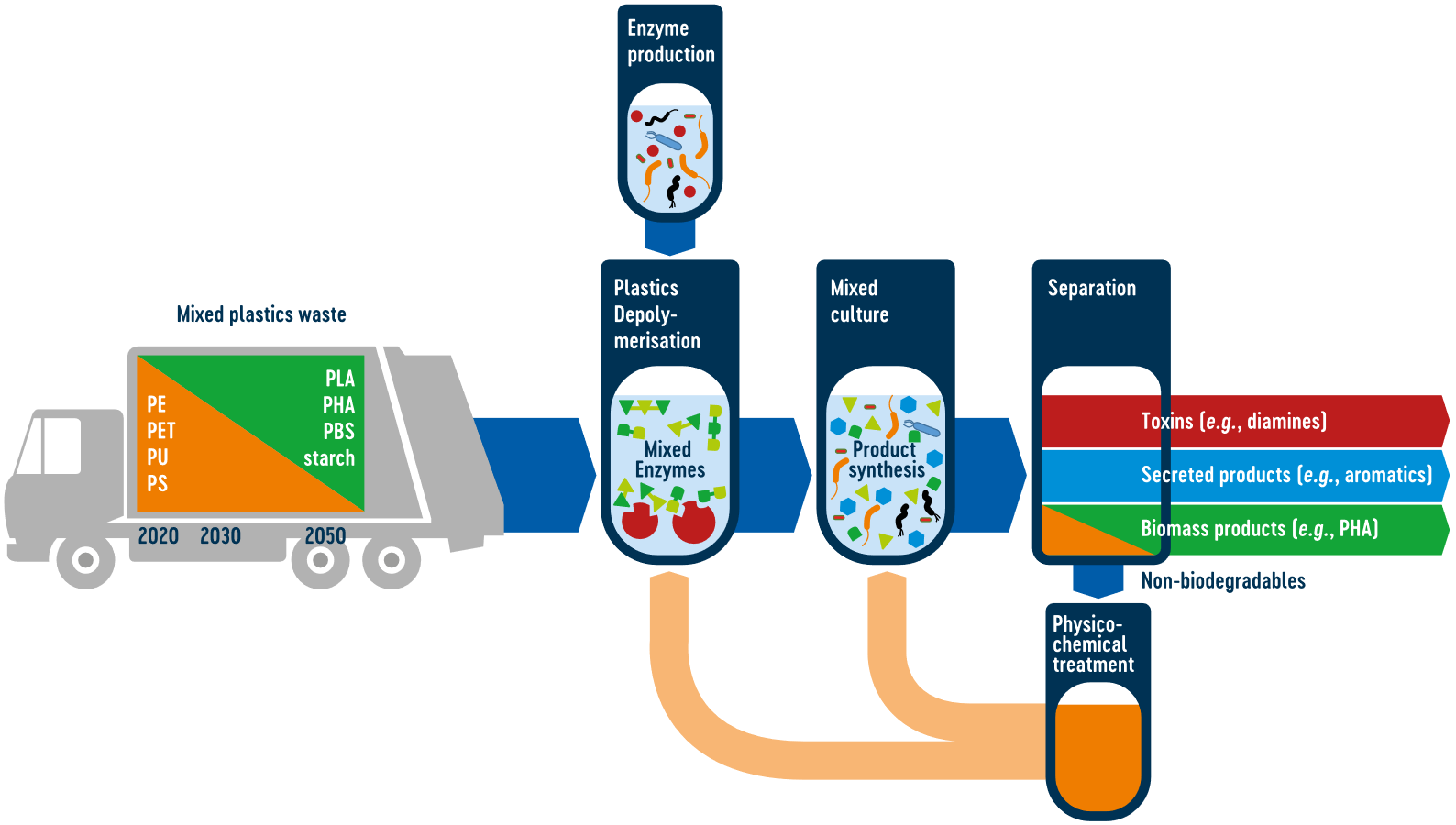

The successor to the EU Horizon 2020 project (P4SB), is ‘MIXed plastics biodegradation and UPcycling using microbial communities (Mix-UP)’. We are expanding the plastics used as a feedstock for industrial biotechnology to mixed plastic waste. The main objective of this project is bioconversion of unsorted, mixed plastic waste into value-added, sustainable bio- materials using engineered enzyme mixtures for depolymerisation and mixed microbial cultures for upcycling of plastic monomers to valuable products. The plastic waste is mixed and its separation to different types of plastics is costly. Our aim is to develop a resource-sorting independent, stable upcycling process for conventional plastics such as polystyrene, polyethylene, and PET, as well as biodegradable plastics whose end of life options could be expanded through our research, e.g. polylactic acid (PLA) and PHA. Once again, the combination of enabling technologies, such as systems and synthetic biology, and non-conventional feedstocks for micro-organisms such as mixed plastic waste will be used to develop bioprocesses to not only reduce, but valorise plastic waste.

The concept of Mix-UP project: Mixed plastic waste will be depolymerised using engineered hydrolysing and oxidising enzymes. In a consolidated bioprocess the depolymerisation is coupled to microbial metabolism to allow the use of the plastic derived feedstock and its conversion to central metabolites, which will provide the building blocks for the synthesis of polymers, chemicals such as vicinal diols, HAAs, bioplasticisers or biosurfactants, or building blocks for chemocatalysis. Finally, Mix-UP will tackle the issue of downstream processing and recovery of the product, thereby showcasing a novel, complete approach to the circularity of plastic. Find out more about the project on our Twitter @MixUP_H2020.

References

1. Tournier, V.; Topham, C. M.; Gilles, A.; David, B.; Folgoas, C.; Moya-Leclair, E.; Kamionka, E.; Desrousseaux, M. L.; Texier, H.; Gavalda, S.; Cot, M.; Guemard, E.; Dalibey, M.; Nomme, J.; Cioci, G.; Barbe, S.; Chateau, M.; Andre, I.; Duquesne, S.; Marty, A., An engineered PET depolymerase to break down and recycle plastic bottles. Nature 2020, 580 (7802), 216-219.

2. Blank, L. M.; Narancic, T.; Mampel, J.; Tiso, T.; O'Connor, K., Biotechnological upcycling of plastic waste and other non-conventional feedstocks in a circular economy. Curr Opin Biotechnol 2020, 62, 212-219.

3. Tiso, T.; Narancic, T.; Wei, R.; Pollet, E.; Beagan, N.; Schröder, K.; Honak, A.; Jiang, M.; Kenny, S. T.; Wierckx, N.; Perrin, R.; Averous, L.; Zimmermann, W.; O'Connor, K. E.; Blank, L. M., Bio-upcycling of polyethylene terephthalate. bioRxiv 2020.

About the Author

Dr Tanja Narancic is an Assistant Professor at the School of Biomolecular and Biomedical Science, University College Dublin. Her research focuses on elucidating the metabolism of bacteria, and using this knowledge and synthetic biology tools to exploit these bacteria to make high value products. More information about her work is available here.