Microbial biominerals for metal catalyst recovery from whisky distillery by-products

The Microbiology Society is undertaking a project entitled A Sustainable Future as part of our 75th Anniversary, which aims to highlight the Sustainable Development Goals (SDGs) to our members and empower them to use their research to evidence and impact the goals. Earlier this year, we put a call out to our members to submit case studies in the following three areas: antimicrobial resistance, soil health and the circular economy.

This case study is written by Richard Kimber, a Research Fellow at the University of Manchester, UK. It focuses on the circular economy; an alternative to a traditional linear economy (make, use, dispose), in which we keep resources in use for as long as possible, extract the maximum value from them while in use, then recover and regenerate products and materials at the end of each service life.

Increasing levels of production and consumption required to meet the needs of our society is creating a twin environmental crisis of resource scarcity and waste generation. A traditional linear economic model of ‘take-make-dispose’ is unsustainable and impacts on environmental quality and human health. The recovery and reuse of resources from waste materials offers a promising solution to reducing our demand for raw resources and minimising waste volumes. This model of ‘use-reuse-recycle’ is an important step towards the transition to the circular economy model of waste treatment and resource management required for a sustainable future.

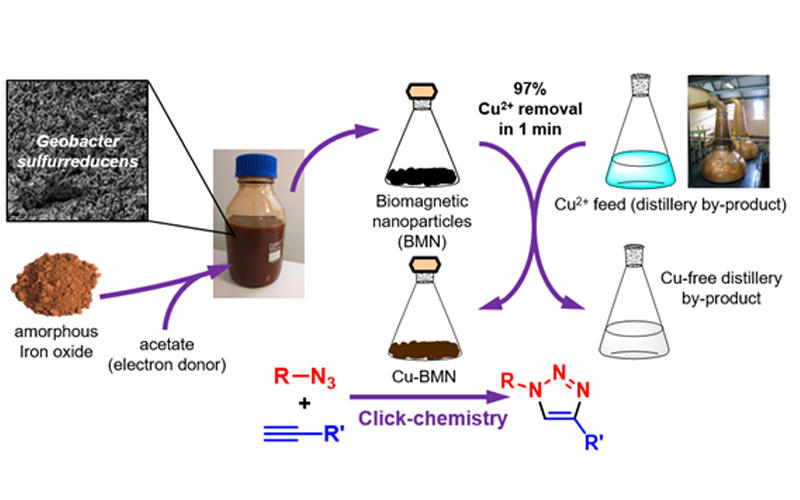

The diversity of micro-organisms makes them ideal candidates for achieving sustainability goals across a wide range of sectors including industrial biotechnology, environmental remediation, agricultural management, and green energy. Our research in this case study has focused on harnessing microbial processes for the recovery of resources from whisky distillery by-products. By-products from the distillation of whisky have potential value as agricultural feedstocks due to their high protein and organic content, however, the presence of high copper concentrations currently limits its use. As copper is itself a useful resource, particularly as a catalyst in many industrial and commercial settings, our goal was to develop a sustainable microbial process for the recovery of this copper as a value-added functional material.

To achieve this, we took advantage of the ability of metal-reducing bacteria to convert widely available iron oxide minerals into highly reactive magnetic nanoparticles. The biological synthesis of these magnetic nanoparticles takes place under environmentally friendly conditions, avoiding the use of aggressive reagents and processing conditions typically associated with chemical synthesis pathways. Application of these biogenic nanoparticles to the distillery products resulted in almost complete removal of all Cu from solution in less than one minute. The copper, which was adsorbed onto the surface of the magnetic nanoparticles, could then easily be separated and recovered from the distillery by-product using a simple magnet. This left behind a Cu-free by-product which could then potentially be applied as a nutrient-rich fertiliser or animal feed.

An added benefit of this approach is that the recovered copper is repurposed as a new value-added resource. The recovered Cu-coated nanoparticles were successfully applied as catalysts for ‘click-chemistry’ – a class of reaction known for being specific, efficient and useful for producing a wide array of high value products from polymers to pharmaceuticals. The magnetic nature of these nanoparticles meant that they too could be recovered and reused in multiple catalytic cycles, adhering to the principles of a circular economy.

This technology offers an environmentally friendly method for the recovery of metals from various waste materials with the added benefit of creating new, value-added functional nanomaterials. This is an important step towards achieving the sustainable management of our waste volumes while simultaneously addressing concerns of dwindling raw resources.

Our lab is working closely with a major whisky distiller, Chivas Brothers, to develop this technology on scale-up from laboratory benchtop to potential in situ pilot treatment. The ability of these micro-organisms to convert waste iron oxides into these useful magnetic nanoparticles could increase the sustainability of this technology and further close the loop between wastes and resources. We are also exploring the wider potential of these micro-organisms to convert a range of other metals from waste sources into functional nanomaterials for biotechnological applications.

Project Team

Richard Kimber (University of Manchester)

Jon Lloyd (University of Manchester)

Fabio Parmeggiani (Politecnico di Milano)

Nick Turner (University of Manchester)

Vicky Coker (University of Manchester)

Dominic Mulroy (University of Manchester)

Ronald Daalmans (Chivas Brothers)

Funding

NERC Resource Recovery from Waste program (NE/L014203/1)

BBSRC (Grants BB/L013711/1 and BB/R010412/1)

Further Reading

R. L. Kimber , F. Parmeggiani , N. Joshi , A. M. Rakowski , S. J. Haigh , N. J. Turner and J. R. Lloyd. Synthesis of copper catalysts for click chemistry from distillery wastewater using magnetically recoverable bionanoparticles. Green Chemistry, 2019, 21 , 4020 —4024. DOI: 1039/C9GC00270G

About the Authors

Dr Richard Kimber is a Research Fellow and Professor Jon Lloyd is a Professor in Geomicrobiology at the Department of Earth and Environmental Sciences at the University of Manchester. More information about their work can be found here.