PHB bioplastic production from waste methane

The Microbiology Society is undertaking a project entitled A Sustainable Future as part of our 75th Anniversary, which aims to highlight the Sustainable Development Goals (SDGs) to our members and empower them to use their research to evidence and impact the goals. Earlier this year, we put a call out to our members to submit case studies in the following three areas: antimicrobial resistance, soil health and the circular economy.

This case study is written by Benedict Claxton Stevens, a PhD student at the Synthetic Biology Research Centre (SBRC), University of Nottingham, UK, and a member of the Microbiology Society. This case study relates to the theme of the Circular Economy; an alternative to a traditional linear economy (make, use, dispose), in which we keep resources in use for as long as possible, extract the maximum value from them while in use, then recover and regenerate products and materials at the end of each service life.

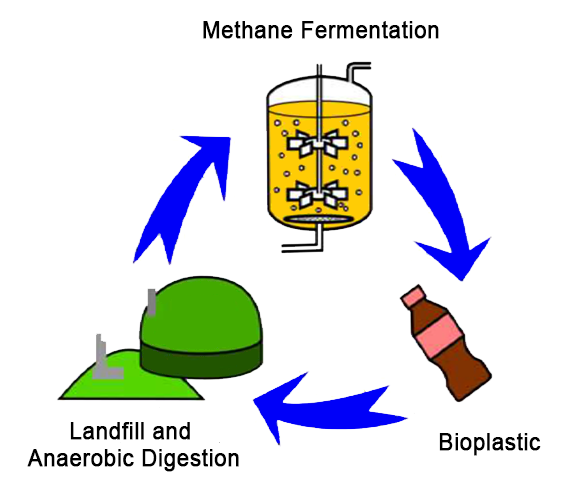

Production of the bioplastic polyhydroxybutyrate (PHB) and its related co-polymers from bacteria offers a green solution to the current plastic crisis. It is biodegradable and can be produced biologically from organic waste sources. PHB is produced by many bacteria but, notably for our case, by certain methanotrophs, which use methane as their sole carbon and energy source. Waste methane including biogas from landfill, agriculture and waste water treatment combined with the fossil fuel industry is 30 times more damaging to the climate per molecule than carbon dioxide, and is the second largest contributor to global warming, causing an estimated 35% of anthropogenic climate change in the last 100 years. Methanotrophs are capable of utilising and thus adding value to low concentration or low-quality waste methane that would otherwise be released to atmosphere, flared, or would require refinement processes before use in electrical generation. This provides progress against two important anthropogenic pollutants, non-degrading plastic waste and waste methane. These are both current major environmental issues.

To qualify as a bioplastic, the PHB must be produced from renewable sources such as biogas captured from landfill or the anaerobic digestion of agricultural, human and food waste. However, industrially scaled methanotroph fermentation often uses fossil fuel methane, undermining its potential green credentials. This is due to the generally higher price of biogas compared to natural gas and concerns about reliability and contaminants in biogas including hydrogen sulphide, ammonia, siloxanes and aromatic and halogenated compounds. Our study tested these issues directly in production along with testing newly isolated strains of methanotroph for improved productivity.

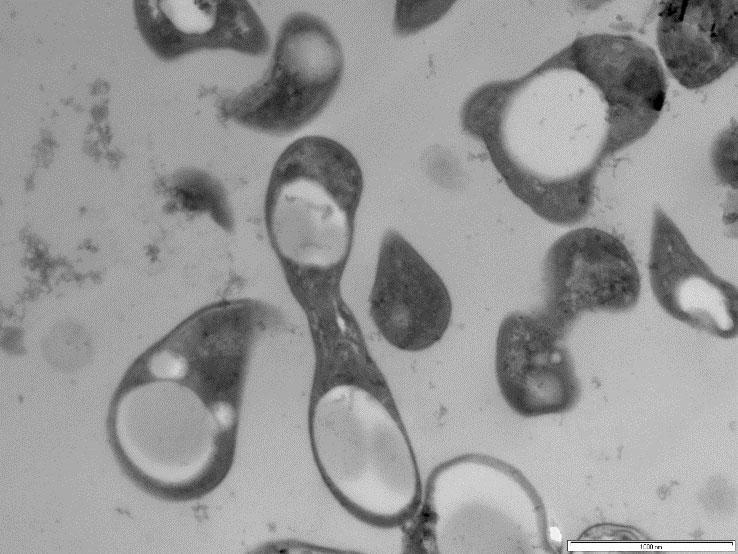

Methylocystis parvus BRCS2 methanotroph bacteria showing PHB bioplastic deposits as the white spots

Biogas from three landfill sites and three anaerobic digesters were tested, covering a range of decomposing matter including shredded corn, food waste, liquid waste, municipal waste and hazardous waste with one sample also testing changes caused by carbon filtration intended to reduce contaminants. No reduced microbial growth was shown on any of the biogas samples compared to pure methane. PHB production was also unaffected producing up to 55.7% dry weight. All sample gasses were tested for contaminants and there was no detrimental effect caused by biogas from different waste sources containing varying levels of detected siloxanes and hydrogen sulphide.

We demonstrated that methanotrophs can produce considerable amounts of PHB on waste methane without impaired growth, which progresses towards its likely final implementation: an in situ plant which could directly use the production of anaerobic digestors of landfill sites to scrub the methane as a cheap or free energy source, also capturing the carbon. The produced bioplastics can be degraded again producing more methane for production and creating a loop in the circular economy. The conclusions of the reliability of growth on biogas are applicable to the production of other products from methanotrophs, including the establishing single cell protein as animal feed production methods from Unibio and Calysta. Waste methane consumption as an integrated process also allows other higher value products from new or engineered methanotroph strains to be produced with minimal change to the fermentation set up further adding value.

The technology still has to deal with certain obstacles, largely relating to economic viability. Although the cost of biogas in comparison to fossil fuel methane or oil for plastic production is currently unfavourable, it appears inevitable that fossil fuel prices will rise as resources are exhausted. At that time, biogas utilising technologies will become very attractive and in the interim subsidy schemes and green credentials motivate usage. Ensuring scientific barriers to the adoption of the technology are bypassed by that time will maximise its uptake and benefit to the climate and economy. Continually improving the fermentation methods at scale up, including induction of PHB production, optimised reactor designs and new or optimised strains to push yields higher will help it be cost competitive and achieve its goals for carbon recycling and capture, and reducing plastic waste.

References

Rumah, B.L., Stead, C.E., Claxton Stevens, B.H. et al. Isolation and characterisation of Methylocystis spp. for poly-3-hydroxybutyrate production using waste methane feedstocks. AMB Expr 11, 6 (2021). https://doi.org/10.1186/s13568-020-01159-4

About the author

Benedict H. Claxton Stevens is a PhD student at the Synthetic Biology Research Centre (SBRC), University of Nottingham, UK, and a member of the Microbiology Society.